Do You Need Geotextile Fabric for Pavers? Is It Helpful?

thepoolanddeck.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com . The website is also an affiliate of a few other brands. The affiliate links never increase your purchase price. We do appreciate your support. Thank you very much!

Table of Contents

Is Geotextile Fabric Needed for Pavers?

Are you planning to build a deck or patio with pavers? “Geotextile Fabric” may have caught your eye in the quotation or your paver dealer may have recommended this product. Unless you are familiar with this product you must have wondered, “Why is Geotextile Fabric needed for Pavers”?

Geotextile Fabric (aka Filter Fabric) is placed between the compacted natural soil and the bottom of the base which consists of ¾” angular stones. Geotextile fabric helps confine the base aggregate and keeps it separated from the subgrade soil while allowing water to drain away.

A non-woven geotextile fabric is recommended for pavers over silt & clay soils.

What Is the Function of Geotextile?

Geotextile Fabric functions like a filter or a one way valve. It permits water to flow from the base aggregates into the subgrade below. However, it does not allow the clay or the silt from the subgrade to move into the base.

Geotextile Fabric extends the life of the paver deck or patio. Without it, a good part of the base stones will get absorbed in the soil below. The base, and ultimately the deck or the patio, will lose its stability and become uneven.

Geotextile Fabric has many other applications besides its use when laying pavers. It is widely used in heavy infrastructure projects such as road & railways, pipelines & irrigation canals, etc.

What Is Geotextile Made From?

Geotextile fabric is mostly made from a synthetic textile material such as polypropylene, polyethylene or polyester. Natural fibers could also be used but they would not meet the fiber degradation resistance requirement.

Geotextile can degrade, when in use, due to

- Organic attacks from microbes

- Inorganic attacks from say extreme pH environments

- Light exposure, usually not a concern

- Aging

Synthetic polymers such as polypropylene, polyethylene or polyester can withstand degradation far better.

What Are the Different Types of Geotextiles?

Geotextile fabrics are either woven or non-woven.

Woven geotextile fabric is made from polypropylene slit films, connected by weaving them on a loom, much like cloth or a jute bag fabric.

Non-woven geotextile fabric is made from polypropylene strands that are connected in a random fashion. This gives it an appearance similar to felt.

They are manufactured by binding short and long fibers together through needle punching or other alternative methods. Heat treatment is applied to improve the bonding and strength.

Two other types of geotextile fabrics are also manufactured for very specialized applications.

Woven monofilament fabrics combine the strength of woven with the permeability of non-woven fabrics.

Spun bound fabrics combine the toughness of woven geotextiles with the permeability of non-woven products.

What Is the Difference Between Woven and Non-woven Geotextile Fabric?

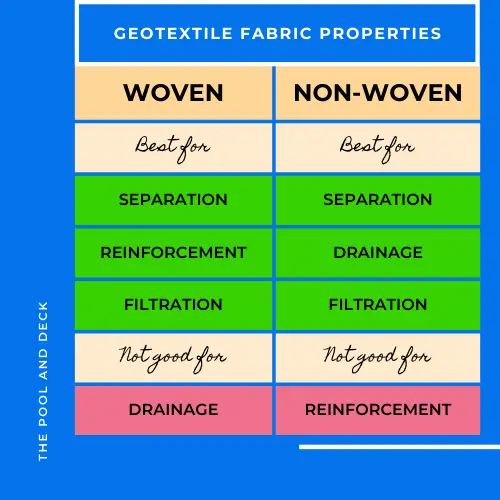

Woven and non-woven Geotextile fabrics differ in the way the polypropylene filaments or strands are connected to each other. This difference results in some difference in properties. This is easy to understand with the infographics below.

Separation is a property that prevents the migration of the subgrade into the base, especially when the base is under compressive stress and the subgrade is soft due to high moisture content.

Reinforcement is a property that helps confine the base aggregates and prevents them from moving sideways under compressive stress.

Filtration is a property that permits the selective movement of particles from one side of the Geotextile Fabric to the other, based on particle size.

Drainage is the property that allows water to flow, from top to bottom, through the Geotextile Fabric.

Is Woven or Non-Woven Better?

Is woven Geotextile Fabric better than non-woven Geotextile Fabric? It all depends on the end use.

Non-woven Geotextile Fabric is, for example, better for pavers. Reinforcement and confinement of the base aggregates is not a major concern for paver patios or decks as they get only light foot traffic.

You can further stabilize your paver patio or deck by placing Paver Base Panels just under the pavers.

Check Out Non-Woven Geotextile FabricWoven Geotextile Fabric is, on the other hand, better for driveways. Reinforcement and confinement of the base aggregates is a major concern as driveways get heavy vehicular traffic.

Check Out Woven Geotextile FabricShould you want good drainage for your driveway, then you could opt to use non-woven Geotextile Fabric and place a GeoGrid on top of it. The GeoGrid will reinforce and confine the base aggregates.

Check Out Geo Grid for PaversDoes Geotextile Fabric Stop Weeds?

It would seem logical to think that non-woven Geotextile Fabric under the pavers will stop weeds from growing in the paver joints. However, this is not the case!

The non-woven Geotextile Fabric is a good 6″ or more under the pavers. It is sitting on the natural soil. Any weed that germinates in that soil and tries to find its way through the non-woven Geotextile Fabric, 6″ or more of base and the paver joints, will sure have a tough task ahead of it.

But weeds that you see on a paver patio did not germinate in the natural soil. They germinated in the sand filling in the paver joints. If you want to stop weeds from growing through the paver joints, re-sand them with polymeric sand.

Thank you very much for reading the post. I do hope you found it informative and helpful.